On October 10-12, the Vietnam International Industrial Expo VIIF2023 came to a successful conclusion. DSTEK has made its debut with multiple star products and solutions: a standardized industrial visual inspection Handdle AI algorithm platform, a self-developed all optical imaging system, deep learning AI intelligent cameras, and AI visual inspection solutions in the lithium/3C/semiconductor field. It provides industrial visual AI inspection solutions that are suitable for multiple scenarios for foreign and local enterprises in Vietnam, including South Korea, Japan, and the United States.

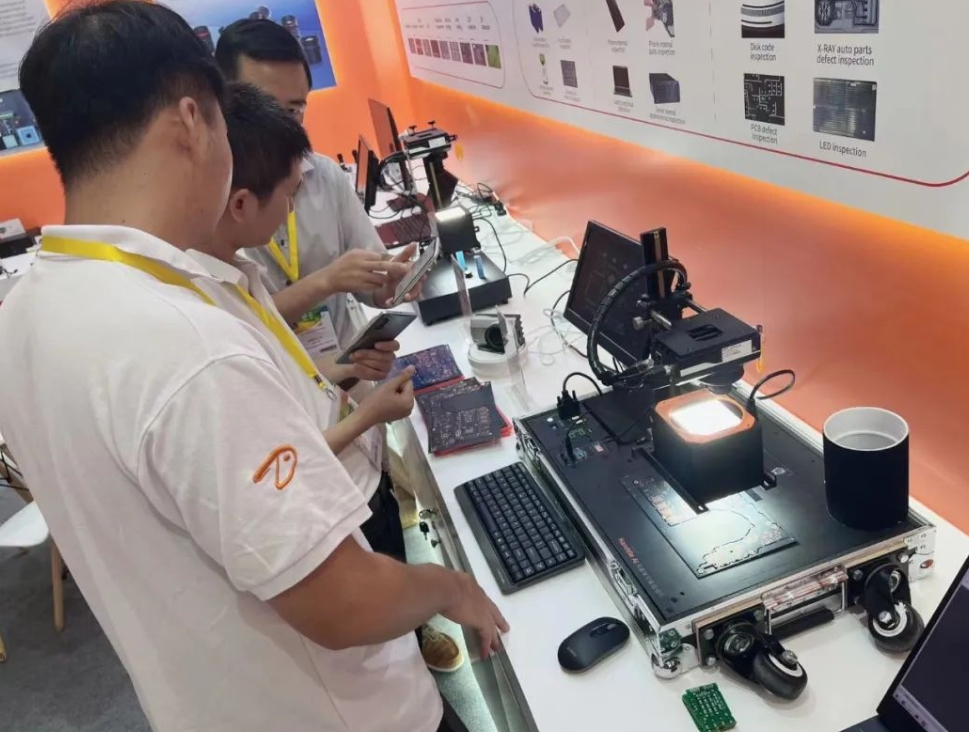

At the exhibition site, customers brought samples for verification and achieved preliminary cooperation intentions with satisfactory results. After the exhibition, we accelerated the implementation of the project. This time, DSTEK has accelerated its journey to Vietnam, exploring more markets and opportunities, meeting more customers and partners, and expanding its brand influence in Vietnam and Southeast Asia.

DSTEK is committed to using the power of AI to transform industry and promote the future development of intelligent manufacturing in Vietnam and even the world. At present, DSTEK's products have successfully entered local enterprises in the United States, Japan, and South Korea, and have been delivered to global factories in the United States, Japan, South Korea, Thailand, Malaysia, Vietnam, Mexico, and other countries. They serve leading enterprises in various industries such as Apple's industrial chain, photovoltaic, lithium battery, Tesla's industrial chain, automotive parts, and semiconductors, including: Flextronics, Lexus Precision, Foxconn, BYD, Tesla, Samsung, LG, SONY, etc Cisco, China Innovation Airlines, Yiwei Lithium, Ganfeng Lithium, Longji Green, FAW Volkswagen, etc.

Strategic layout, accelerating expansion

As a leader in AI industrial vision, DSTEK 's research and development team focuses on the deep cultivation of AI machine vision, dedicated to new research and development, new technologies, and new applications. They have accumulated rich project implementation experience, and rely on self-developed standardized AI software and hardware products and self-developed optical imaging solutions to occupy a good market share. They have achieved particularly significant results in fields such as pan 3C, new energy lithium batteries, and pan semiconductors.

Pan 3C field: DSTEK has implemented projects on 3C consumer electronics product production lines such as mobile phones, laptops, tablets, and watches, including defect detection of mobile camera modules, glass defects of mobile phone cover plates, battery cover defects, internal component defects, middle frame/RT peripheral defects, smart watch strap defects, and overall appearance defects of laptops.

Lithium battery field: DSTEK provides detection solutions for square power batteries, square energy storage batteries, large cylindrical batteries, small cylindrical 18650 and 4680 cylindrical batteries. Among them, for square aluminum shell batteries, our company provides an overall solution from process inspection to final inspection of blue film coating. Covering from pole segments, cell segments to module segments, Including: foil incoming inspection/coating appearance inspection/roller split appearance inspection/mold split appearance inspection/bare cell surface appearance inspection/ultrasonic welding inspection/positive and negative polarity inspection of soft connectors/post welding inspection of soft connectors/package Mylar inspection/pure aluminum shell flatness inspection/shell welding seam inspection/top cover laser welding inspection/liquid injection inspection/sealing nail laser welding inspection/square aluminum shell appearance final inspection/square coating appearance final inspection, as well as PACK section Busbar inspection, etc Process inspection requirements.

In the field of pan semiconductors: DSTEK has achieved batch implementation in the field of pan semiconductors such as wafers/chips/capacitors/resistors/LEDs, including LED bead appearance defect detection/wafer appearance defect detection/capacitors, resistor appearance defect detection/crystal oscillator appearance defect detection, etc.

As a company focused on serving the global field, DSTEK will continue to provide international sales and technical support services in the future. Our company will continue to focus on landing projects in overseas markets and global factories, working together with world leading partners to serve global customers, providing excellent product quality and service experience, providing efficient technical support and after-sales service, promoting the development of the intelligent manufacturing industry, and unleashing the maximum value of AI!

Media cooperation:pr@dstekai.com

Talent recruitment:dshr@dstekai.com