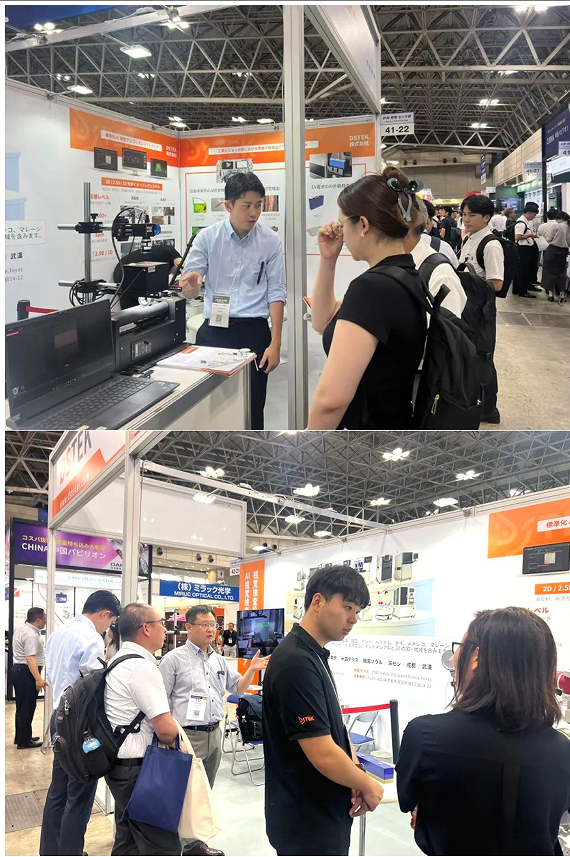

From July 9–11, 2025, the highly anticipated Tokyo Industrial Expo in Japan was held with great fanfare. As a global technology leader in industrial AI vision inspection, DSTEK once again showcased its industrial AI vision product lineup with a stunning debut.

At this expo, Mitsui Group—a centuries-old Japanese conglomerate with over 400 years of history and immense influence—participated as DSTEK’s strategic partner. Through deep collaboration, they jointly expanded into the Japanese market, demonstrating China’s cutting-edge industrial AI vision capabilities to global clients.

During the expo, DSTEK highlighted its industrial AI vision-embedded robots, AI-powered inspection solutions for automotive bearings/engines, lithium battery AI inspection systems, and PCBA AI vision detection schemes. On-site, DSTEK engaged in in-depth discussions and partnership negotiations with multiple renowned Japanese companies and potential global clients, further expanding its international market presence.

Focusing on the Japanese market, DSTEK has forged even closer ties with existing partners while establishing a new cohort of strategic allies, laying a solid foundation for its future in-depth development in Japan. To date, the company has successfully served global renowned enterprises such as SONY, YKK, and KOA, delivering production lines for factories across Japan, Thailand, Malaysia, and other countries.

DSTEK's products and technical services now span over 20 countries and regions worldwide, with large-scale applications in high-end manufacturing sectors such as 3C electronics, new energy lithium batteries, and automotive industries, covering more than 15,000 production lines. This underscores its formidable competitiveness and influence in the global wave of intelligent manufacturing upgrades.

Deep Industry Penetration: Solving Industrial Quality Inspection Challenges

Currently, DSTEK's products and technical services are widely applied across industrial scenarios:

Consumer Electronics (3C): Inspection scenarios include full visual inspections and component testing for smartphones, laptops, industrial computers, tablets, and smartwatches.

Automotive: Inspection covers AI-powered defect detection in welding, online battery housing inspections, automatic door/lid assembly, gap and flushness online measurement, OCR recognition, and visual inspections of automotive stamped parts and components.

New Energy Batteries: Full-process quality control and final visual inspections for lithium batteries, including prismatic, cylindrical, and pouch cells across all production stages.

Semiconductor: Inspection encompasses chips, surface-mount LEDs, capacitors, and inductors.

From automotive components to new energy lithium batteries, and from 3C consumer electronics to semiconductor sectors, Dongsheng Intelligence's AI vision inspection solutions are injecting powerful momentum into the global manufacturing transformation.

The 2025 Tokyo Industrial Expo marks another pivotal milestone in Dongsheng Intelligence's development. Through this event, the company not only achieved technical recognition and market expansion but also reinforced its commitment to driving global manufacturing intelligence through innovative technologies. Moving forward, Dongsheng Intelligence will continue to uphold its principles of innovation, collaboration, and mutual benefit, tirelessly exploring new frontiers to contribute greater wisdom and strength to the prosperity of global manufacturing.

Media cooperation:pr@dstekai.com

Talent recruitment:dshr@dstekai.com